South End Elevators

Mutual/Electric Elevator

In 1916, the Mutual Elevator Company built their 500,000-bushel elevator on the Kaministiquia River turning basin. The workhouse was wooden crib with metal cladding, and its annex was concrete. In 1926, the terminal increased its capacity to 1,000,000 bushels with a new concrete annex and also added a new dock, revetment walls, a shipping gallery, new conveyors, and more loading spouts.

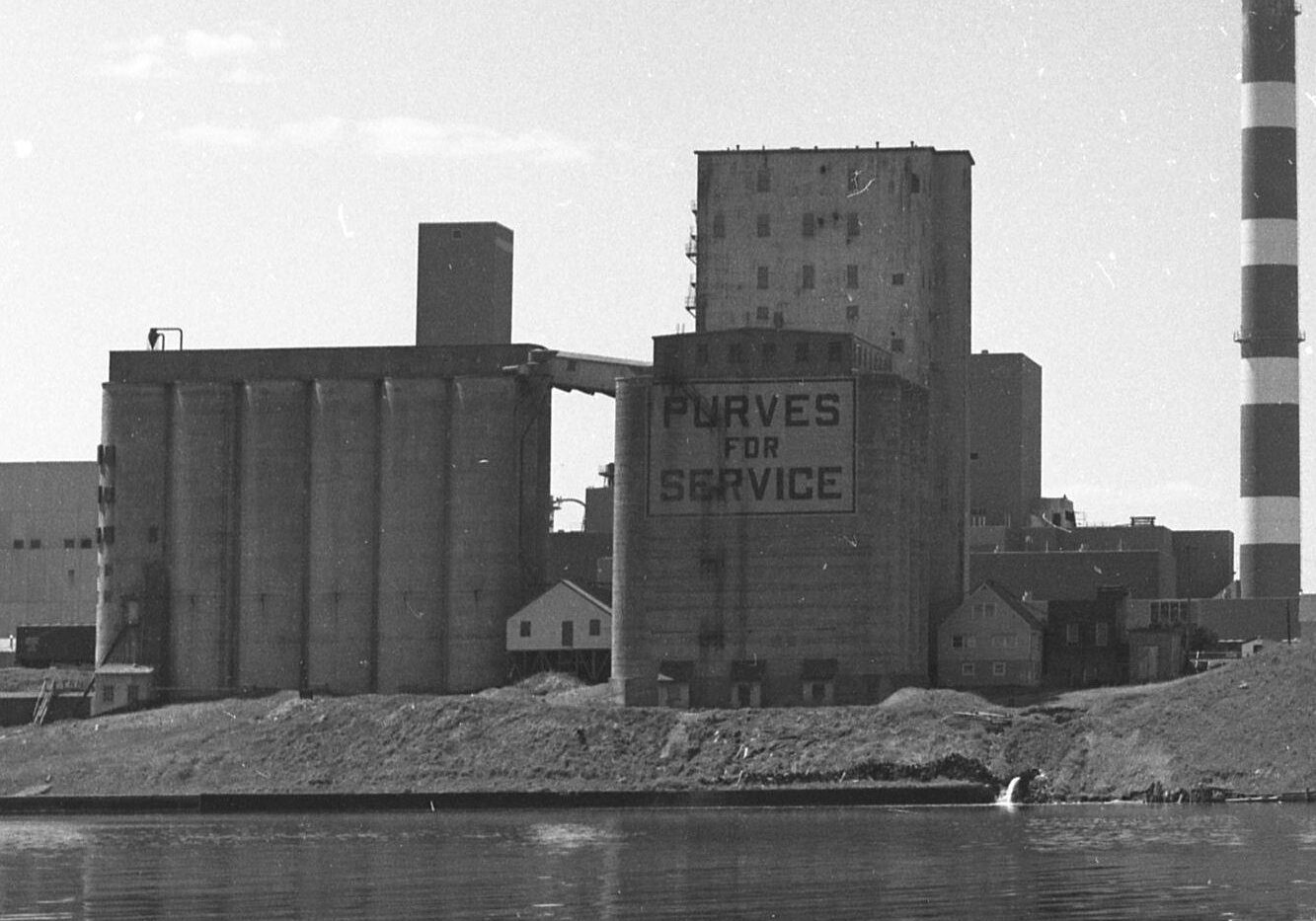

This little elevator changed hands many times over its years—more than any other elevator in the Lakehead. The Bole Grain company, headed by Fred Bole, bought the terminal and renamed in the Electric Elevator in the 1920s. When Fred Bole went to prison in 1930 for falsifying the elevator’s warehouse receipts, the terminal was bought and became the Phoenix Elevator. After the terminal briefly closed in 1936, McCabe Grain Company resurrected the operations as their “C” elevator in 1937. Inter-Ocean Grain Company operated the terminal between 1946 and 1965 as Lakehead Terminal A. In 1950, the terminal put up a “Purves for Service” sign, named after one of the Inter-Ocean owners, Robert Purves. By 1966, the elevator was owned by Federal Grain and operated under the same name.

A fire broke out in 1969 when the elevator was in the process of demolition, and the whole elevator was quickly torn down. The site is now vacant.

Overview

Original Name:

Date of opening:

Designer:

Builder:

Initial Owner:

Current Owner:

Mutual Elevator

1916

Fegles Engineering

Fegles Engineering

Mutual Elevator Company Ltd.

--

Capacity:

Piles:

Initial Railway Service:

Geographic Service:

Operating:

1,000,000 bushels or 27,200 tonnes

--

Canadian Northern

48.350498, -89.3044743

No, demolished

Black and Muirhead

The Black and Muirhead was the first terminal grain elevator built on the upper Kaministiquia River on what is known as the turning basin. In 1909, the terminal could hold 100,000 bushels of grain in 48 bins. The terminal was built in an outdated wooden crib design with corrugated iron cladding, and it sat on a concrete foundation. It was a 128-foot tall and narrow structure with a one-storey attached car shed. An addition in 1914 of a similar shape and design increased capacity to 200,000 bushels. The addition took only 37 days to complete with 50 workers. The owners claimed that all three national railways (CPR, CNoR, and GTPR) could reach the terminal, and it had a long enclosed gallery used for shipping. The terminal was primarily a hospital elevator, modelled after the prosperous CPR operation in Port Arthur.

A devastating fire in 1919 levelled the wooden elevator to the ground. The cause was determined to be an overheated bearing. When firemen arrived, they couldn’t control the flames, so they focused efforts on saving the nearby Mutual and Northwestern elevators. The land was sold shortly after the fire in 1919 to a company who hoped to build another elevator on the site, but the plans fell through. The land is currently vacant.

Overview

Original Name:

Date of opening:

Designer:

Builder:

Initial Owner:

Current Owner:

Black and Muirhead

1909

Barnett-McQueen (additions)

Barnett-McQueen (additions)

Black and Muirhead Company

--

Capacity:

Piles:

Initial Railway Service:

Geographic Service

Operating:

200,000 bushels or 5,440 tonnes

--

Canadian Northern

48.351674, -89.304807

No, demolished

Northwestern

Plans for the Northwestern’s construction began in 1916, and the 500,000-bushel cement and tile elevator was completed on the Kaministiquia River turning basin a year later. It was the last terminal constructed on the Kam River turning basin. The Northwestern Elevator Company was created by John Charles Gage and Henry Sellers, a third-generation elevator operator. The Sellers family was famous in the Lakehead industry—Henry’s father Harry Sellers weighed the first terminal grain shipment in 1885, and grandfather Matthew Sellers managed the CPR’s first Fort William terminals. Due to this strong connection, the Northwestern was sometimes called the M Sellers Elevator.

The terminal was unique in the Lakehead due to its angular orientation. The workhouse and the two annexes that extended in either direction were all joined at diagonal angles. The Northwestern could unload 120 cars in 10 hours and had four loading spouts on its riverside annex. In 1924, a fire destroyed the workhouse, 30,000 bushels of grain, and seven boxcars. The elevator could still ship its 1,400,000 bushels of remaining grain using the annex machinery, but it couldn’t receive any new grain until the workhouse was replaced. By 1932, the terminal had a 3,000,000-bushel capacity.

The Northwestern was eventually owned by Federal Grain and was demolished by 1977. The elevator met its demise due to the high price of new dust control equipment and the lack of dredging on the Kaministiquia River.

Overview

Original Name:

Date of opening:

Designer:

Builder:

Initial Owner:

Current Owner:

Northwestern

1917

F.R. McQueen

--

Northwestern Elevator Company

--

Capacity:

Piles:

Initial Railway Service:

Geographic Service:

Operating:

3,000,000 bushels - 81,600 tonnes

--

--

48.353874, -89.304711

No, demolished

Paterson

NM Paterson & Sons built a 140,000-bushel wooden elevator on the upper Kaministiquia in 1914 with immediate plans for expansion. A 10-bin concrete annex and connecting gallery were built in 1917—this date is often cited as the construction date for the whole elevator. Although measures were taken to keep the hazardous wooden workhouse separated from the annex, a fire in 1926 destroyed the workhouse and parts of the annex. The elevator was completely rebuilt out of concrete, and its capacity increased to 2,500,000 bushels. As primarily a hospital elevator, the Paterson’s new design had two cleaning floors—the first of its kind in the Lakehead. In 1930, another annex was built on the Paterson lot away from the river and the main elevator structure. The bins were only 74 feet high but were twice as wide as was normal at 59 feet. The roof was sloped, which was unusual for elevator structures. This annex alone had a 2,000,000-bushel capacity and was connected to the main elevator with a raised gallery. With this annex, the Paterson’s total capacity grew to 4,500,000 bushels.

Richardson International leased the terminal in 1969 to store their low-demand grains. By 1975, the terminal—sometimes called Richardson B—operated only on a part-time basis. Unable to afford dust control upgrades, foundation repairs, and costly river dredging, the Paterson closed in 1977. Demolition of the elevator began in 1978 and was drawn out for months into 1979. The Paterson dock is still visible at the site, where the historic James Whalen tugboat is docked for viewing.

Overview

Original Name:

Date of opening:

Designer:

Builder:

Initial Owner:

Current Owner:

Paterson

1914

Fegles Engineering

Barnett-McQueen

N.M. Paterson & Sons

--

Capacity:

Piles:

Initial Railway Service:

Geographic Service:

Operating:

4,000,000 bushels - 108,800 tonnes

--

Canadian Pacific

48.360022, -89.286214

No, demolished

Saskatchewan Wheat Pool 5

Western Terminal had a multi-stage construction that began in 1909. Barnett-McQueen built the first 900,000-bushel unit with a tile and steel workhouse and a tile and concrete annex. The annex’s 32 bins were 89 feet high and 21 feet in diameter. The second unit was built right next to the first in 1914 entirely of reinforced concrete. The 88 new bins increased capacity to 2,000,000 bushels. The third concrete unit increased capacity to 3,100,000 bushels and added a carshed to the operation. The full operation could unload 12 cars per hour and had a loading speed of 35,000 bushels per hour. A fourth structure, a hospital elevator, was also added to the site in 1917, but it was operated by a separate company, Western Grain. In order to reach the river from its inshore position, the company built an enclosed loading gallery that ran the entire length of Western Terminal down to the dock. This small elevator had a capacity of 250,000 bushels, and eventually joined the terminal’s operations in 1929. At this time, the companies merged and the whole operation changed its name to Western Grain. This terminal was one of the Lakehead elevators that built temporary wartime storage on its property during World War II.

Saskatchewan Wheat Pool bought the elevator in 1963 and renamed it Pool 5. The terminal ceased operations in the late 1970s and was demolished soon after in 1980. The elevator site is vacant, but remnants of the wartime storage foundations and the underground connecting belts still remain.

Overview

Original Name:

Date of opening:

Designer:

Builder:

Initial Owner:

Current Owner:

Western Terminal

1909

Barnett-McQueen

Barnett-McQueen, Fegles Engineering (expansion)

Western Terminal Elevator Company

--

Capacity:

Piles:

Initial Railway Service:

Geographic Service:

Operating:

3,100,000 bushels - 84,300 tonnes

--

Canadian Pacific

48.362015, -89.278282

No, demolished

Western Grain By-Products Storage

The Fort William Elevator, last known as Western Grain By-products, is a gem of an elevator on the north bank of the Kaministiquia River, which empties into Lake Superior. The site includes railway, storage & handling, and water shipping components. The elevator, which received its first shipment in 1913, was a state of the art terminal that incorporated cutting edge construction techniques. The FWE Company ran a full-page ad proudly outlining the terminal’s innovative features.

With a capacity of 1,750,000 bushels, Western Grain has successfully transferred millions of tonnes to receiving ports around the world.

Overview

Original Name:

Date of opening:

Designer:

Builder:

Initial Owner:

Current Owner:

Fort William Elevator

1913

Barnett-McQueen

Barnett-McQueen

Fort William Elevator Company

To be announced

Capacity:

Piles:

Initial Railway Service:

Geographic Service:

Operating:

1,750,000 bushels - 48 concrete bins

2,500 locally sourced jack pine piles

Canadian Pacific

48.351802399999999, -89.282596300000002

No, decommissioned

Consolidated Elevator

The Consolidated elevator was constructed in two phases, giving the terminal is distinctive “double elevator” look. The first side was constructed in 1907 by Barnett-McQueen. The annex bins were tile construction, and the workhouse was tile, brick, and reinforced concrete. The 85-foot-high bins were arranged 4x8 and had gently sloped bottoms. The tile and brick workhouse was 157 feet high. The second workhouse and annex were constructed in 1910 by James Stewart and Company. Both annex and workhouse on the second elevator were entirely reinforced concrete. The concrete workhouse was taller at 167 feet, and the concrete bins were arranged 3x8 with steeply sloped bottoms, also 85 feet high. Enclosed galleries connected both workhouses and annexes. The now 1,750,000-bushel capacity elevator had 2 receiving tracks which held 35 cars each. At the time, the elevator was considered on of the most efficient rapid handling elevators in the Lakehead—though the company boasted it was one of the fastest in the world.

Consolidated Elevator Company eventually sold their terminal to the Fort William Elevator Company, changing the name to Fort William Elevator E. In 1971 Saskatchewan Wheat Pool bought the terminal and renamed it Saskatchewan Wheat Pool 11. The elevator was decommissioned in the late 1970s and is now owned by the Province of Ontario. The elevator remains standing on the banks of the Kam River.

Overview

Original Name:

Date of opening:

Designer:

Builder:

Initial Owner:

Current Owner:

Consolidated

4 June 1907

Barnett-McQueen James Stewert and Co.

Barnett-McQueen (tile) James Stewert and Co. (concrete)

Consolidated Elevator Company

Province of Ontario

Capacity:

Piles:

Initial Railway Service:

Geographic Service:

Operating:

1,750,000 bushels or 47,630 tonnes

--

Canadian Pacific

48.362860, -89.273154

No, decommissioned

Westland D

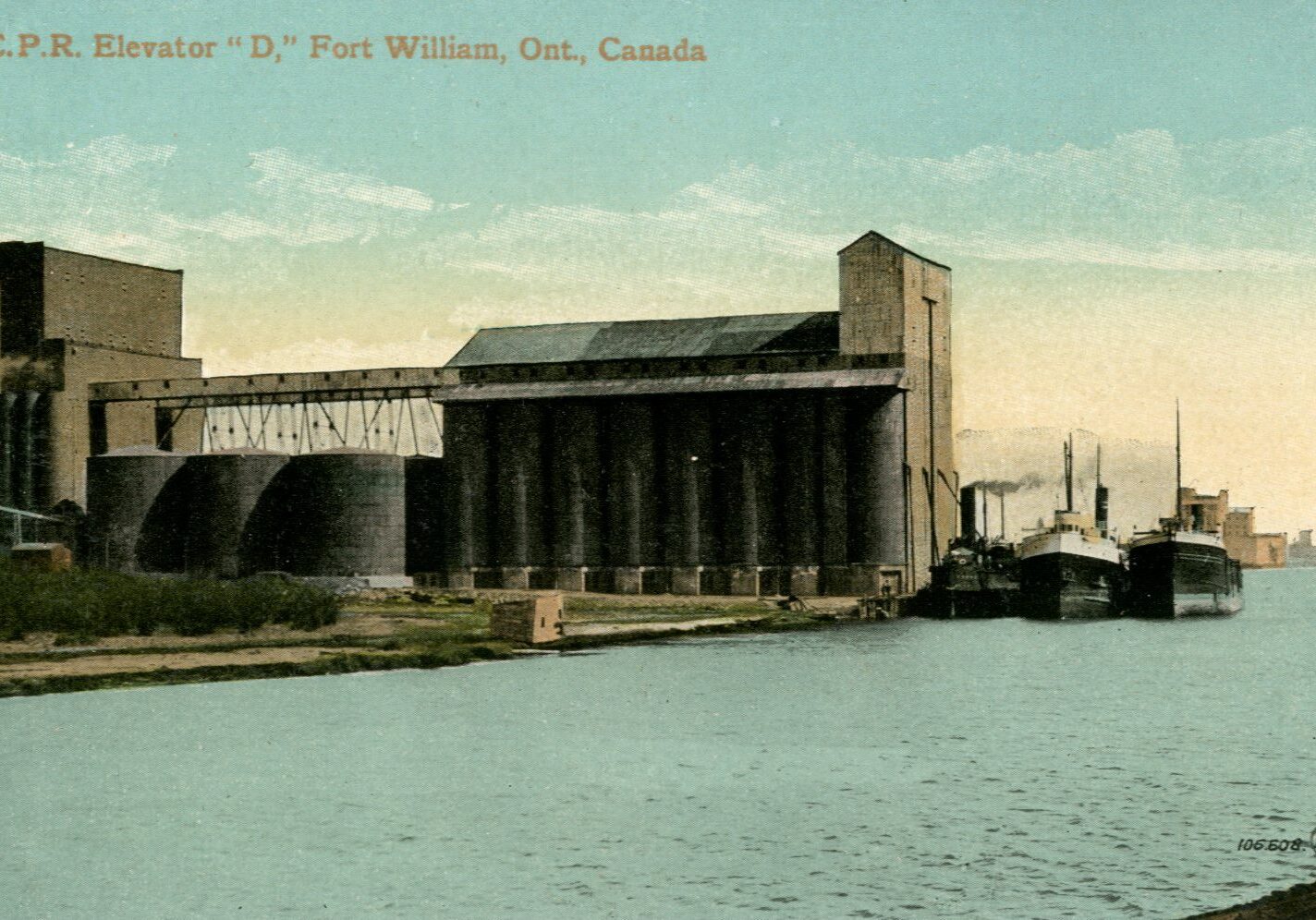

CPR Elevator D, nicknamed the “House of Mysteries”, was jointly built by F.J. Weber and the Steel Storage Company of Buffalo in 1897. The elevator was built up at a bend in the Kaministiquia River away from the CPR’s other wooden terminals. The terminal was constructed in the “new” design of having separate structures for its different functions. The wooden workhouse was attached to a set of 24 95-foot-high steel tanks and a set of 32 75-foot-high steel tanks. An overhead enclosed conveyor ran along a trestle and emptied into each bin. The 1,750,000-bushel capacity annex was the largest in the Lakehead at the time. Although the steel tanks were meant to be fireproof, the elevator burned down in 1902—only the boiler and engine room stayed standing. The steel bins were reconstructed, and a wooden workhouse was added in 1903, but by 1906 another fire ravaged the workhouse. Barnett-McQueen built the new tile workhouse, and later replaced the whole elevator with a concrete reconstruction. With more expansions in 1914, Elevator D’s capacity grew to 7,500,000 bushels—then the largest in the world. The 1914 version of the elevator could unload 160-200 cars in 10 hours. If all 16 loading spouts were in operation, it had a loading speed of 200,000 bushels per hour.

Elevator D became the Northland in the 1920s when it was leased by Federal Grain and Searle Grain during bumper crop years. By 1946, Federal Grain exclusively operated the elevator. In 1951, James Richardson & Sons jointly purchased the elevator with Federal under a new company, Westland Elevator Limited, and renamed the terminal Westland D. Saskatchewan Wheat Pool bought the terminal in 1972 and renamed it Pool 17, but it closed only two years later in 1974. The terminal was eventually demolished, and the site is now vacant.

Overview

Original Name:

Date of opening:

Designer:

Builder:

Initial Owner:

Current Owner:

CPR Elevator D

1897

F.J. Weber and Company

Steel Storage Company of Buffalo

CPR

--

Capacity:

Piles:

Initial Railway Service:

Geographic Service:

Operating:

7,750,000 bushels or 210,900 tonnes

11,000

Canadian Pacific

48.363974, -89.260707

No, demolished

Ogilvie Elevator and Flour Mill

Ogilvie Elevator and Flour Mill was constructed between 1904 and 1905 by Macdonald Engineering Company of Chicago. The original structure was a single unit with annex storage below and workhouse operations above, sitting right on the Kaministiquia riverbank. On May 26, 1906, the whole structure slid 50 feet off of its foundation and toppled into the river, destroying hundreds of thousands of bushels of grain and costing millions of dollars in damages. The new elevator was built well back from the riverbank out of heavy iron plate by the same Chicago company. A raised loading gallery was added to the workhouse to reach ships in the river. Two annexes were eventually added to this unit: one of steel in 1914, and one of concrete in 1949. Bins in both units were 100 feet high, and the total capacity grew from 500,000 bushels to 3,000,000 bushels. The elevator had an attached flour milling operation, which was the first of its kind in Fort William. These separate buildings included a 5-storey flour mill that could process 4000 barrels of flour per day, a feed plant, a warehouse, and flour storage bins. Dust control was added to both operations in the 1970s due to new regulations and complaints from the surrounding neighbourhood.

Ogilvie sold the elevator and mill to Saskatchewan Wheat Pool in 1960, and the operation became Pool 8. The terminal briefly closed in 1987 and was briefly reopened by Riverside Grain in the late 1990s. A fire in 2001 destroyed almost all of the milling operation, but the terminal remained untouched. Calls for the elevator’s demolition were halted in 2019, and the elevator remains standing.

Overview

Original Name:

Date of opening:

Designer:

Builder:

Initial Owner:

Current Owner:

Ogilvie

1905

--

J.A. Macdonald and Company

Ogilvie Flour Mills

Unknown

Capacity:

Piles:

Initial Railway Service:

Geographic Service:

Operating:

3,000,000 bushels - 81,600 tonnes

--

Canadian Pacific

48.3751230, -89.248021

No, decommissioned

Dwyer/Gillespie

The Dwyer elevator, sometimes called an “elevator and sacking plant”, was built in 1913 on Thunder Bay’s Mission Island. The workhouse was an outdated wooden construction 155 feet in height, but it had a unique sloped gable roof. The 28 annex bins held just 100,000 bushels, but a concrete addition in 1915 raised capacity to 250,000 bushels. The Dwyer had simultaneous loading and unloading capabilities, extensive cleaning and drying equipment, and it uniquely had a grain sacking room over its carshed. This allowed the Dwyer to sack grain and load it directly onto railcars from its scales.

The Dwyer Elevator Company sold its elevator to the Gillespie Grain Company in 1920. Not long after the ownership change, the wooden workhouse caught fire and rendered the elevator nonoperational. Gillespie moved its operations to the historic King’s terminal in Port Arthur, and the Dwyer’s concrete bins were left standing on Mission Island for decades. The bins were eventually demolished, and the site is now vacant.

Overview

Original Name:

Date of opening:

Designer:

Builder:

Initial Owner:

Current Owner:

Dwyer

1913

--

T.T. Ibberson

Dwyer Elevator Company

--

Capacity:

Piles:

Initial Railway Service:

Geographic Service:

Operating:

250,000 bushels - 6,800 tonnes

--

Canadian Pacific

48.375320, -89.244084

No, demolished

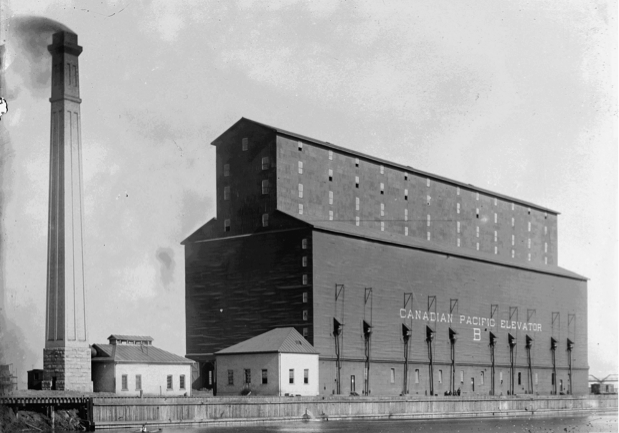

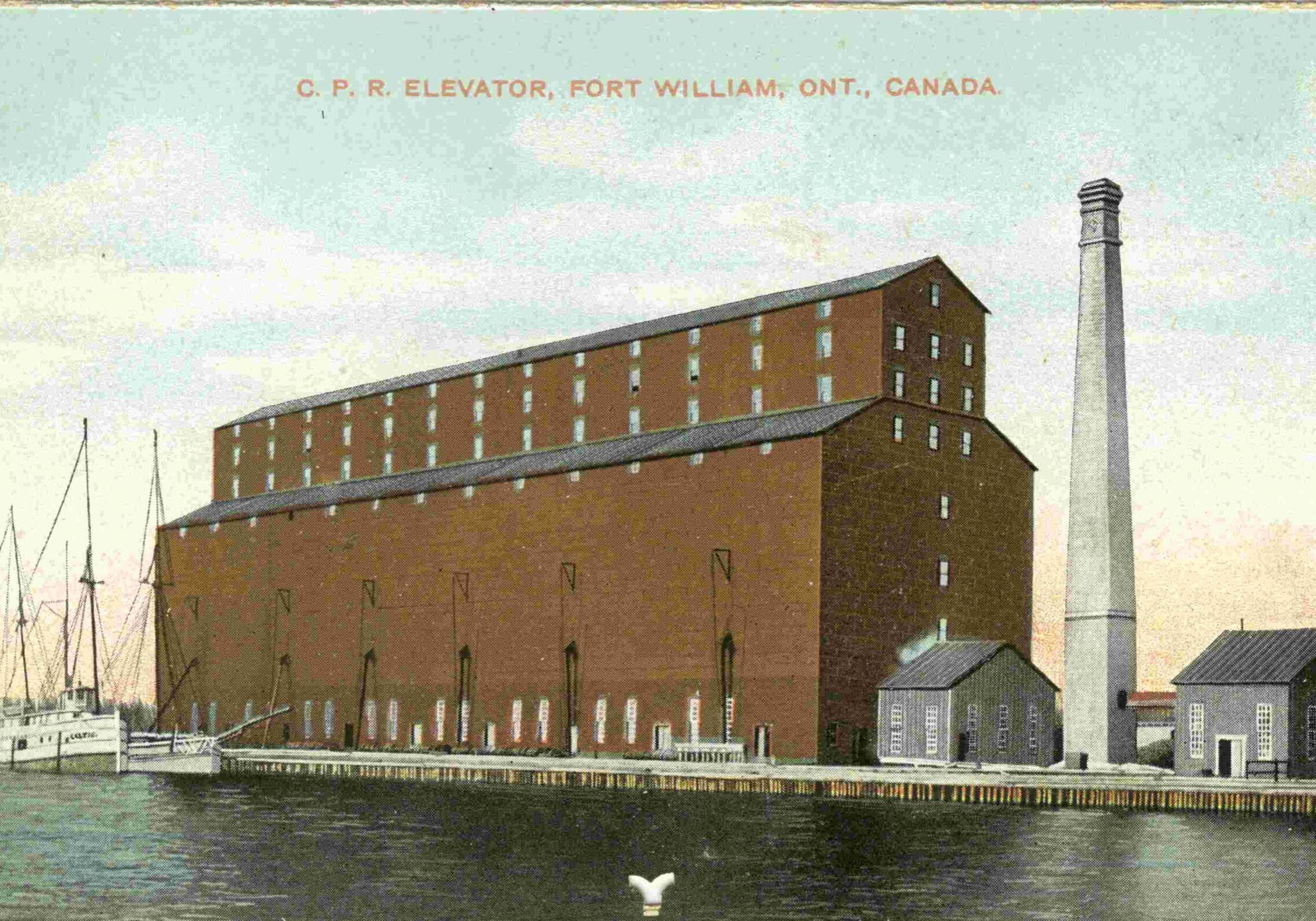

CPR B

Constructed between 1888 and 1889 by the CPR’s bridge and building department, Elevator B stood at the foot of Victoria Avenue in Fort William’s business district. The original elevator was essentially a copy of Elevator A, having a 1,000,000-bushel capacity in an entirely wooden structure. Disaster struck on May 12, 1904, when a fire burned the whole elevator to the ground. Barnett-McQueen reconstructed the elevator by 1905 using less-flammable steel, tile, brick, and concrete. Unlike the previous design, the new Elevator B now had more distinct structures for its annex, workhouse, and carshed functions. The elevator had 1 interior and 2 exterior rail tracks, with an unloading speed of 110-120 cars every 10 hours. Combined with Elevator E—which it operated wit—Elevator B had a loading speed of 50,000 bushels per hour. As 95% of the received grain was dirty, the terminal had 14 cleaners.

Elevator B and E were leased to Grain Growers Grain Company in 1912 before they built their own terminal in Port Arthur in 1916. The terminal continued to be used on and off for overflow storage, but it was eventually demolished with Elevator E in 1947. The still-active CPR rail yard now traverses the empty elevator site. Parts of Elevator B’s docks are still visible in the Kaministiquia River Heritage Park.

Overview

Original Name:

Date of opening:

Designer:

Builder:

Initial Owner:

Current Owner:

CPR B

1889

CPR's W.J. Ross; Barnett-McQueen (reconstruction)

CPR's W.J. Ross; Barnett-McQueen (reconstruction)

CPR

--

Capacity:

Piles:

Initial Railway Service:

Geographic Service:

Operating:

500,000 bushels - 13,600 tonnes

--

Canadian Pacific

48.383694, -89.241181

No, demolished

CPR E

Elevator E was the last CPR terminal to be constructed when the Macdonald Engineering Company of Chicago built it between 1902 and 1903. The 2,000,000-bushel elevator replaced a freight shed that stood between Elevators A and B. The elevator was an annex for Elevator B, connected to the other terminal with a steel, iron, and tile conveyor gallery. Elevator E was also connected to Elevator A with a wooden conveyor passage. Although it is called Elevator E, many historic records don’t label the structure as its own unit, but only as extra storage for Elevator B. The terminal had 84 steel tanks, which were each 80 feet high with a 20-foot diameter. A new workhouse in 1904 built by Barnett-McQueen increased the capacity by another 500,000 bushels. It was leased to Grain Growers Grain Company alongside Elevator B in 1914, and the two elevators were demolished together in 1947. The still-active CPR rail yard now traverses the empty elevator site.

Overview

Original Name:

Date of opening:

Designer:

Builder:

Initial Owner:

Current Owner:

CPR E

1903

Macdonald Engineering Company

CPR

CPR

--

Capacity:

Piles:

Initial Railway Service:

Geographic Service:

Operating:

2,500,000 bushels - 68,000 tonnes

--

Canadian Pacific

48.385443, -89.238842

No, demolished

CPR A

After building their first terminal in Port Arthur, the CPR built a huge 1,000,000-bushel terminal along the Kaministiquia River between 1884 and 1885. Like the Port Arthur elevator, CPR A looked like a single large warehouse with its storage on the bottom and its workhouse operations in an upper cupola. The 133-foot-high elevator was built entirely of wood by the CPR’s bridge and building department. All 211 storage bins were square and 60 feet tall. A simple wooden storage annex with 1,300,000-bushel capacity was built 340 feet away from Elevator A to deal with grain overflow—Elevator C eventually replaced this structure. A single unloading rail track ran through the entire building and could handle 80 cars every 10 hours. From its 11 shipping spouts, Elevator A had a loading capacity of 30,000 bushels per hour. Continual repairs were performed on the elevator’s foundations due to the uneven settling of piles that affected the weighing scales.

Though originally built as an annex for the CPR terminal in Port Arthur, Elevator A became a prosperous operation in its own right, leading the CPR to build 4 more terminals in Fort William. The first shipment of grain left Elevator A in 1885. James Richardson & Sons’ Eastern Terminal Elevator Company leased Elevator A and C in 1914 before building their own terminal in Port Arthur. Elevators A and C were demolished in 1927 because of fire hazards and lack of use. The CPR’s still-active rail yard now traverses the empty elevator site.

Overview

Original Name:

Date of opening:

Designer:

Builder:

Initial Owner:

Current Owner:

CPR A

1884

CPR's W.J. Ross

CPR's D. Leary Brothers

CPR

--

Capacity:

Piles:

Initial Railway Service:

Geographic Service:

Operating:

2,300,000 bushels - 62,595 bushels

--

Canadian Pacific

48.396340, -89.237373

No, demolished

CPR C

The CPR’s Elevator C was built between 1890 and 1891 on the site of Elevator A’s storage annex. The CPR hired J.A. Jamieson to convert the storage unit into an elevator to make the movement of grain between the units easier. Elevator C, though called an elevator, couldn’t operate independently, so it relied heavily on the unloading and loading equipment in Elevator A. The terminal did, however, have 6 cleaners and a single loading spout of its own. The 1,250,000-bushel wooden elevator had 174 bins that were each 65 feet tall. As it was 340 feet away, Elevator C connected to Elevator A using a single conveyor belt enclosed in wood that ran the entire 340-foot distance. Eastern Terminal Elevator Company leased Elevator C with Elevator A in 1914, and the two elevators were demolished together in 1927. The still-active CPR rail yard now traverses the empty elevator site.

Overview

Original Name:

Date of opening:

Designer:

Builder:

Initial Owner:

Current Owner:

CPR C

1891

J.A. Jamieson

J.A. Jamieson

CPR

--

Capacity:

Piles:

Initial Railway Service:

Geographic Service:

Operating:

1,250,000 bushels or 34,000 tonnes

--

Canadian Pacific

48.387174, -89.236182

No, demolished

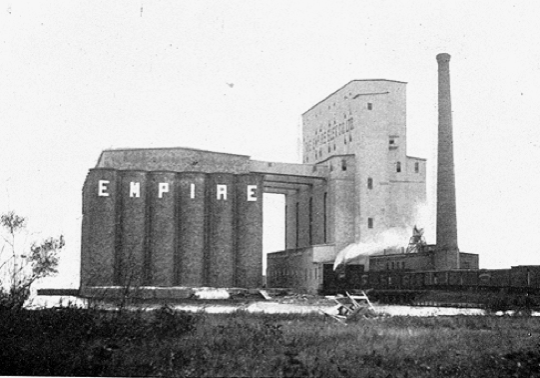

Empire Elevator

The Empire was the first non-railway-owned elevator in the Lakehead. The Empire Elevator Company—a conglomeration of line elevator companies—hired Barnett-McQueen to build their 1,750,000-bushel elevator at the mouth of the Kam River in 1904. To prevent shifting, piles were placed tightly together under a thick concrete foundation. The Empire was built in the “new” style of having separate structures for the terminal’s different functions. Its wooden workhouse had 49 small square bins, and the annex had 48 95-foot-high circular bins. The annex was built using vitrified tiles, which was a new construction method at the time. This method would become a Barnett-McQueen signature elevator style in the coming decade. The annex was built at a distance beside the workhouse due to fears of fire, and this orientation of parts soon became popular along the waterfront. The carshed had 2 tracks and could unload 150 cars in 13 hours. With its 8 loading spouts, the Empire had a loading capacity of 40,000 bushels per hour.

The Empire was eventually bought by the Fort William Elevator Company, who soon sold to Saskatchewan Wheat Pool in 1966. Pool 12, as it came to be called, dwindled in use before its planned demolition. While dismantling the elevator in 1970, a fire broke out and burned the original wooden workhouse down. The tile annex was demolished a year later using dynamite—the first demolition by dynamite in the Lakehead. The dock dismantled in 1987, so no pieces of the terminal remain.

Overview

Original Name:

Date of opening:

Designer:

Builder:

Initial Owner:

Current Owner:

Empire Elevator

1904

Barnett-McQueen

Barnett-McQueen

Empire Elevator Company Ltd.

--

Capacity:

Piles:

Initial Railway Service:

Geographic Service:

Operating:

1,750,000 bushels

--

Canadian Pacific

48.394071, -89.215860

No, demolished

G3 Terminal

Constructed in 1928, the Searle Terminal Elevator, now known as G3, was constructed in 1928 on Mission River. Able to hold 3,000,000 bushels, it's construction contract was fulfilled by Fegles Construction Company at the cost of approximately $1,000,000. The elevator was advertised as being unique to previous elevators due to a difference in the design of the overall structure. The elevator featured fire-proof reinforced concrete, a car shed, a drier,

two stroage annexes, a wheat washer, office building, and a garage. The elevator's ambitious construction period allowed it to thrive without the need for additions, meaning the elevator's day-to-day operations went relatively unchanged until 1972 where Searle became Sasketchewan Pool #15 due to a change in ownership and again in 1991 where the elevator

ceased operation entirely. Eventually, the elevator was converted into a Fiber Fuel Products plant and later came under ownership of G3 where it currently serves as their Thunder Bay terminal.

Today, G3 currently operates at 200 Darrel Avenue and has a capacity of 137,740 tonnes. More information can be found at https://www.g3.ca/facility/g3-thunder-bay.

Overview

Original Name:

Date of opening:

Designer:

Builder:

Initial Owner:

Current Owner:

Searle

1928

C.D. Howe

Fegles Construction Company

Searle

G3

Capacity:

Piles:

Initial Railway Service:

Geographic Service:

Operating:

3,000,000 bushels (1928) - 137,740 tonnes (2019)

--

Canadian Pacific

48.35745486610609, -89.22910622321069

Yes

Superior

Currently open and operational at 140 Darrel Ave, Superior Terminal is one of the few elevators that has withstood the test of time and the changing of the grain trade. Part of a partnership between Cargill and Parrish and Heimbecker, Superior began operation in 1910 as the Grand Trunk Pacific elevator, an elevator that received notoriety due to a photograph of the building being used on a widely circulated European postcard (find photo, refer to) published by Valentine and Sons.

The elevator's sustainability can be contributed to the way it was built. When the elevator was being designed, architects made a point to construct an elevator that would support future additions. For example, at the beginning of its construction, the elevator's capacity during its starting years was 3,250,000 bushels, but the elevator was designed to support at least

60,000,000 bushels with future additions.

Overview

Original Name:

Date of opening:

Designer:

Builder:

Initial Owner:

Current Owner:

Grand Trunk Pacific

1910

R.H. Folwell

W.R Sinks, John S. Metcalf

Grand Trunk Pacific

Cargill, Parrish & Heimbecker

Capacity:

Piles:

Initial Railway Service:

Geographic Service:

Operating:

3,250,000 bushels (original) - 176,020 tonnes (current)

--

Grand Trunk Pacific Railway

48.35495326646581, -89.23086985945702

Yes